RC Plane + Lift Testing Kit

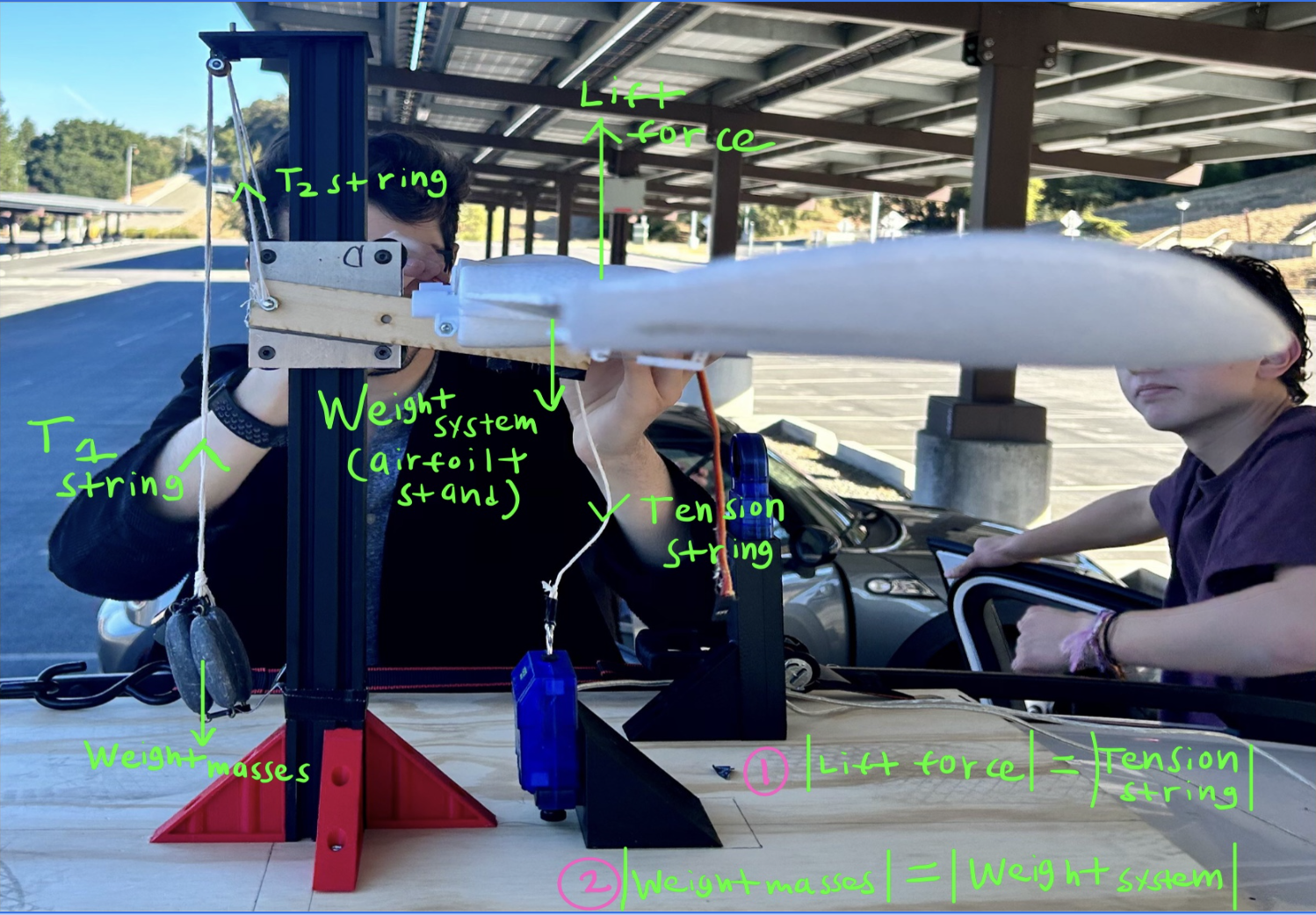

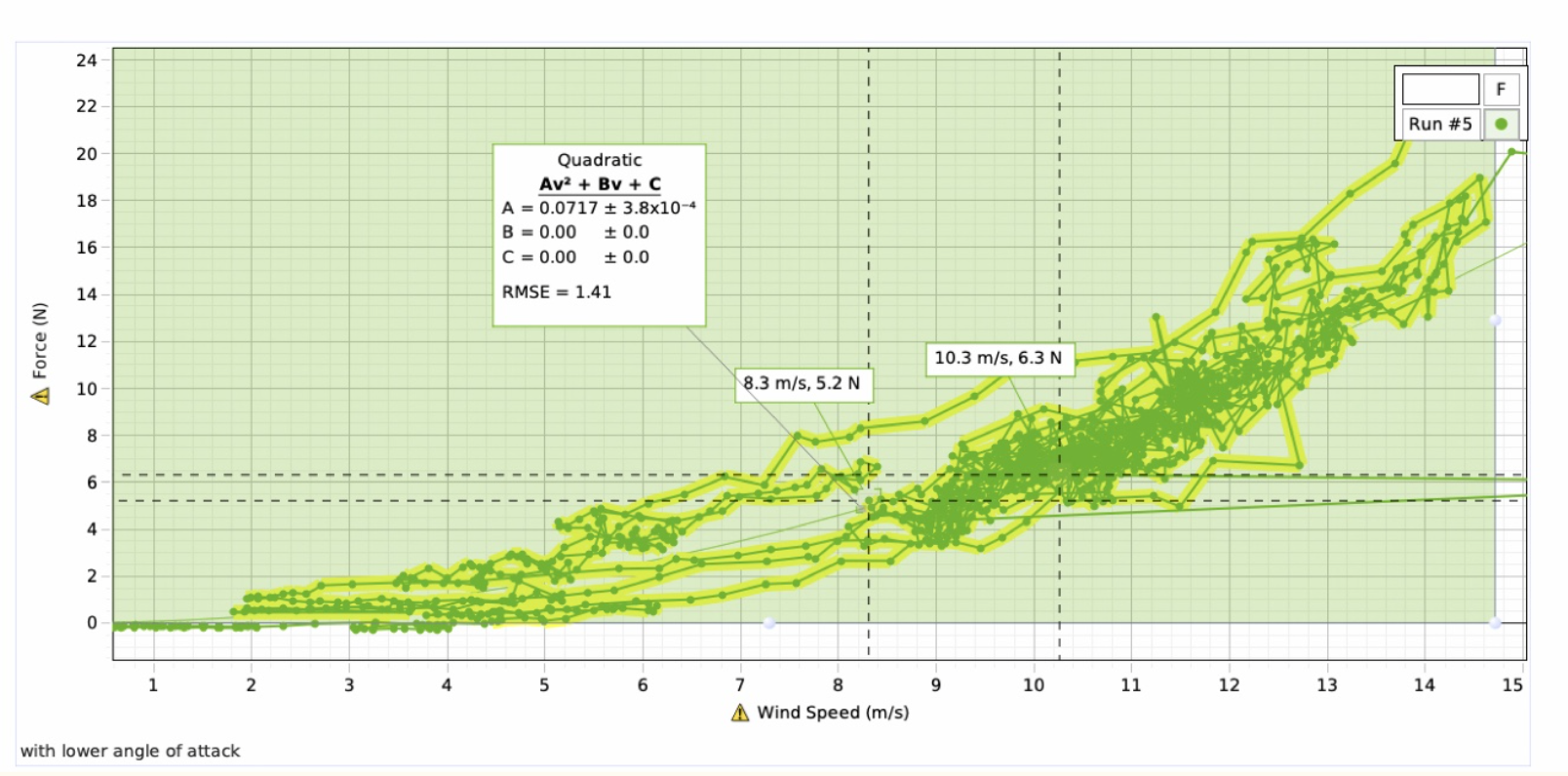

The LiftKit3 was developed as a tool to calculate lift coefficients for non-uniform airfoils . The system, mounted on a vehicle, utilized sensors to measure lift and airspeed, allowing for the creation of lift-to-airspeed graphs. This data was crucial for refining aircraft performance and served as a practical substitute for traditional wind tunnel testing.

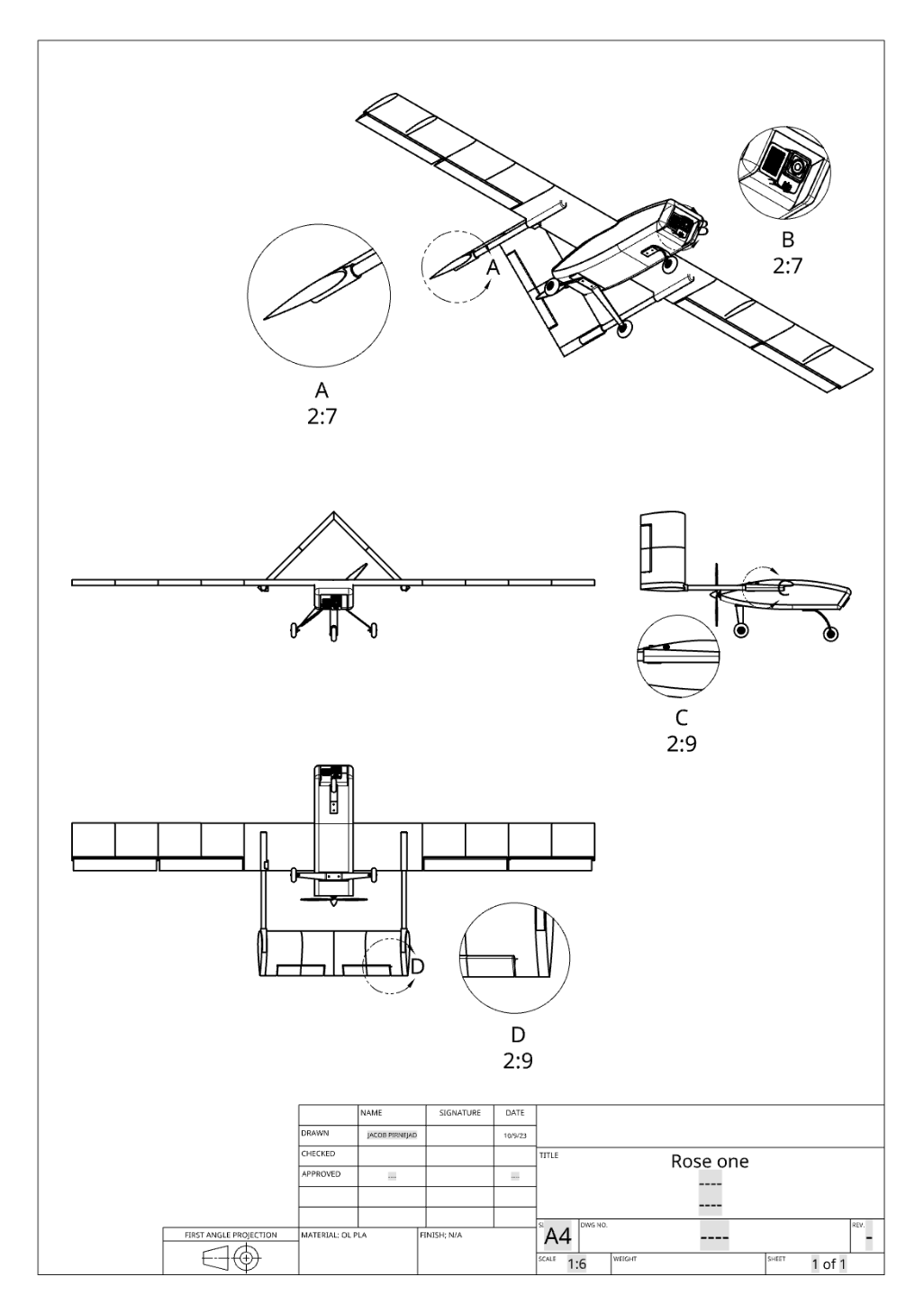

Project ROSE was an RC aircraft initiative aimed at building a long-range unmanned flight vehicle. It served as a practical learning experience to apply academic concepts such as statics, properties of materials, and mechanics. The project went through multiple iterations, utilizing foam board and 3D-printed components, with plans to incorporate composite materials.

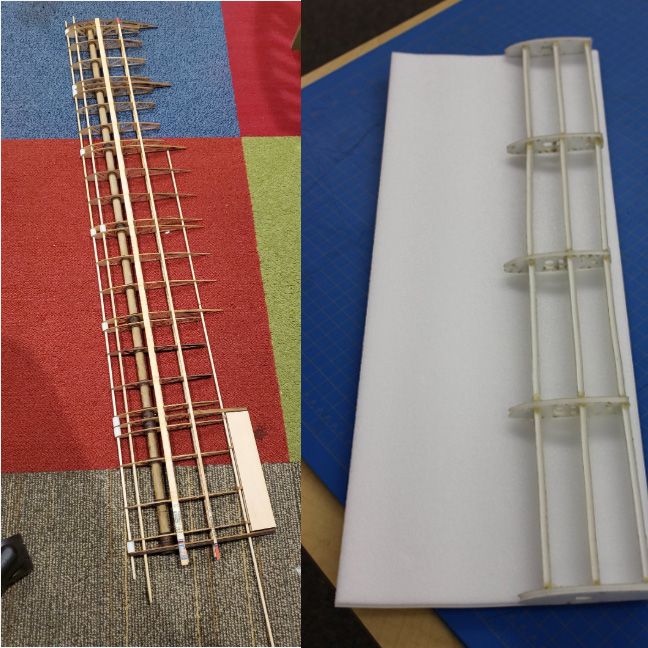

Initial Use of Balsa Wood. The first iteration of the aircraft utilized balsa wood, inspired by the structural design of World War II era aircraft. This choice was influenced by its lightweight nature and ease of assembly, making it an ideal material for a team with limited CAD experience.

Transition to Foam Board: We moved to foam board to explore the use of sandwich materials, which offered a better balance of strength and weight. The foam board cores provided a solid foundation while remaining lightweight and easy to work with.

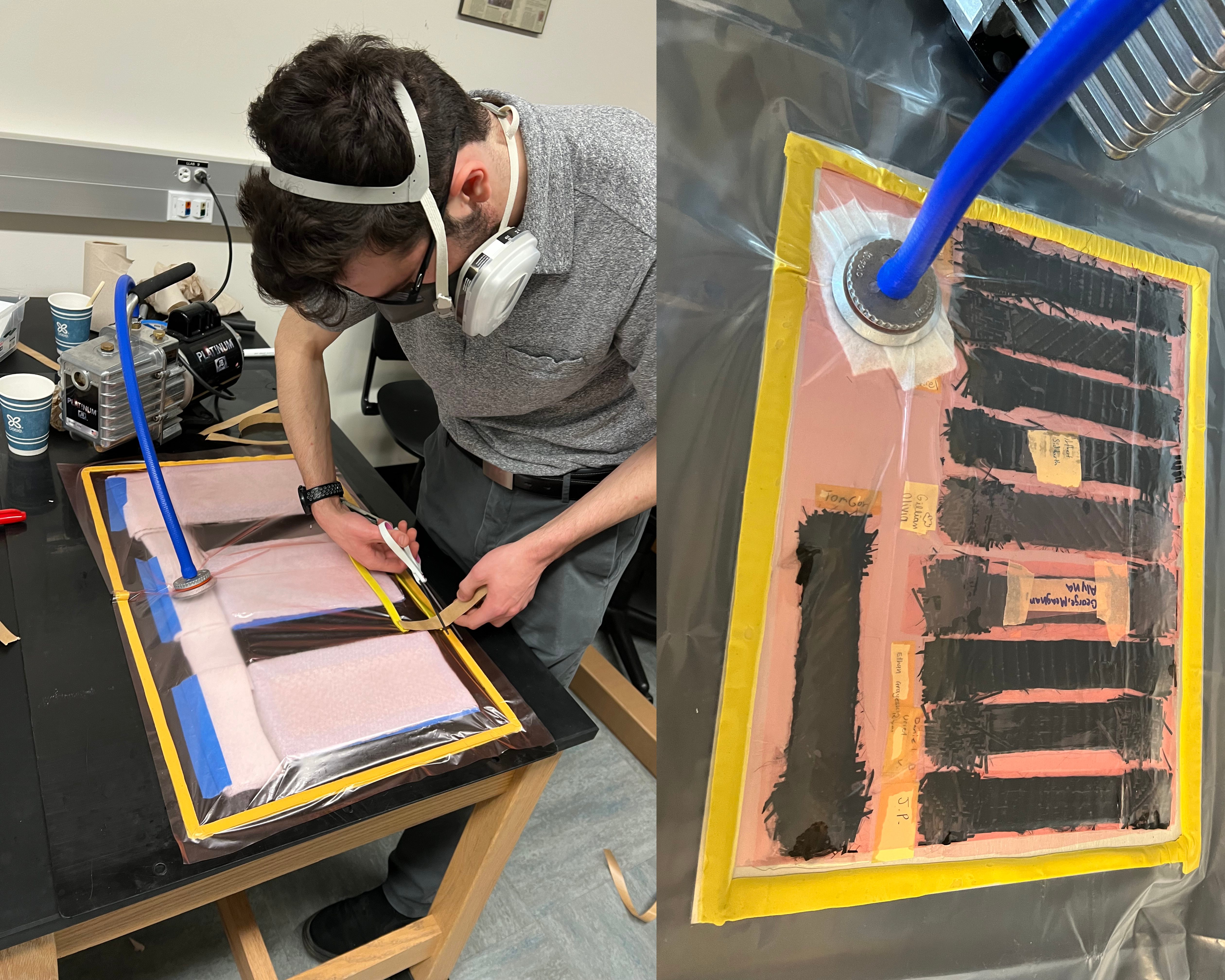

Integration of Composite Materials: To enhance the structural integrity of the foam board, we began applying a thin layer of fiberglass composite material to the outer walls. This approach gave us stronger wings without significantly increasing the overall weight, making the design more efficient.

Fiberglass Infusion Method: We successfully developed an infusion method to create the external housing of the airfoil using fiberglass. This process showed promise for future iterations, where we planned to apply the same technique with carbon fiber for even greater strength.